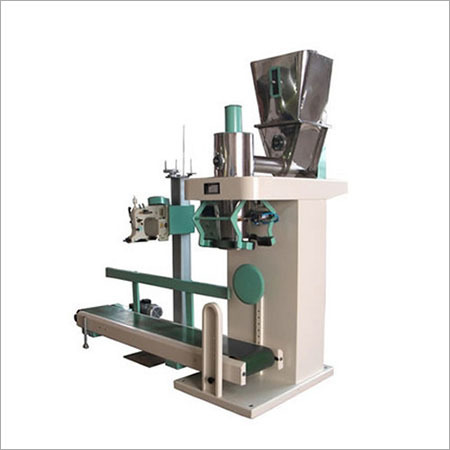

Dry Mortar Material Packing Machine

Price 354000.00 INR/ Unit

MOQ : 1 Unit

Dry Mortar Material Packing Machine Specification

- Type

- Packaging Line

- Capacity

- 250 Kg/hr

- Power

- 30-40 Watt (w)

- Voltage

- 230-240 Volt (v)

- Color

- Silver

Dry Mortar Material Packing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Standard

- Main Export Market(s)

- Asia, Australia, Africa

- Main Domestic Market

- All India

About Dry Mortar Material Packing Machine

We are leading manufacturer of Dry Mortar Material Packing Machine and we manufacturing these machine as per customer requirement and we are dealing in all over India. The provided mortar is used to construct residential and commercial complexes. Our offered mortar is widely applauded in the market by our patrons owing to its quality. Under the supervision of adroit professionals, the provided mortar is processed with the aid of advanced tools and machines.

Technical Details : Dry Mortar Material Bag Packing Machine

Features of Dry Mortar Material Bag Packing Machine

- Retention of important properties of spices like taste, flavour and colour

- Maintains uniform quality of product.

- Easy and economical dust free operation

Technical Details : Dry Mortar Material Bag Packing Machine

- Capacity : 20-50 KG

- Power : 10 HP

- Usage/Application : Industrial

- Bag Type : Metalized, Stand Up Barrier, PP/ LD

- Brand : SIGMA

- Material : Mild Steel

- Voltage : 400 V

- Size: Footprint 900mm(W), 1440mm(L), 1950mm(H)

- Electric: Base Machine Is 380-415 VAC 3 Phase 50Hz 1.5 AMPS

- Power: as Per Customer Request

- Bag Weight: 5-50kg

Efficient and Reliable Packaging Solution

Our Dry Mortar Material Packing Machine guarantees accuracy and reliability in every batch. With a consistent output capacity of 250 kg per hour, businesses can increase productivity while maintaining exact packing standards for mortar materials. The advanced design reduces downtime and enhances workflow across industrial environments.

User-Friendly and Durable Design

Designed for both ease of use and durability, this packaging machine features a streamlined interface and sturdy construction. It's equipped to handle daily operations with minimal maintenance required, making it an ideal addition for manufacturers and suppliers seeking long-term performance and low operational costs.

Energy-Efficient and Versatile Operation

Operating within a 30-40 Watt power range and standard 230-240 Volt supply, this machine ensures minimal energy consumption without sacrificing efficiency. Its adaptability makes it suitable for diverse packaging requirements within the construction materials sector, keeping energy bills low while delivering consistent quality.

FAQ's of Dry Mortar Material Packing Machine:

Q: How does the Dry Mortar Material Packing Machine operate?

A: The machine automates the packing of dry mortar materials by accurately weighing and dispensing the product into packaging, ensuring consistency and minimizing waste during high-speed operations.Q: What types of businesses can benefit from this packing machine?

A: Manufacturers, suppliers, and exporters of dry mortar materials, especially those needing efficient packaging solutions in India, will find this machine particularly valuable for scaling up production and maintaining consistent output quality.Q: When is the best time to use this packaging machine in a production line?

A: This machine is ideally integrated after the blending process and before storage or shipment, as it ensures materials are uniformly packed and ready for transport or sale, optimizing workflow efficiency.Q: Where should the machine be installed for optimal performance?

A: It's best to place the machine in a dry, dust-free environment near the production area with easy access to electrical outlets (230-240 Volt) to streamline material flow and maximize operational efficiency.Q: What is the packing process for dry mortar material in this machine?

A: Dry mortar is loaded into the machine, which then measures and fills the specified quantity into packaging materials automatically, completing the cycle quickly while minimizing manual intervention.Q: How is this machine beneficial compared to manual packing methods?

A: This automatic packing solution increases production speed, reduces labor costs, ensures consistent packaging, and significantly minimizes spillage and product loss.Q: What safety features are incorporated in this packing machine?

A: The design includes overload protection and user-friendly controls to ensure operator safety and prevent any electrical or operational hazards during everyday use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Material Packaging Machine Category

25 Kg Bag Filling and Hot Sealing Machine

Price 480000 INR / Set

Minimum Order Quantity : 1 Set

Type : Sealing Machines

Voltage : 440 Volt (v)

Automatic Grade : Automatic

Capacity : 250 Kg/hr

Masonary Mortar Bag Filling System

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Filling Machine

Voltage : 400 Volt (v)

Automatic Grade : SemiAutomatic

Gram Packing Machine

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Packaging Line

Voltage : 230 Volt (v)

Automatic Grade : SemiAutomatic

Capacity : 250 Kg/hr

Movable Bag Filling Machine

Price 468000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Filling Machine

Voltage : 220 Volt (v)

Automatic Grade : SemiAutomatic

|

SIGMA INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry