Silage Vacuum and Sealing Machine

Price 1250000 INR/ Unit

Silage Vacuum and Sealing Machine Specification

- Power

- 65 Watt (w)

- Voltage

- 220 V

- Dimension (L*W*H)

- 1220 mm x 680 mm x 1020 mm

- Electric Current Type

- AC

- Automatic Grade

- Semi-Automatic

- Filling Capacity

- 20-60 kg per bag

- Condition

- New

- Machines Type

- Vacuum Sealing Machine

- Control System

- Digital Panel or Push-Button Controls

- Weight

- Approx. 220 kg

- Input Power

- Single Phase Electric

- Material

- Mild Steel

- Sealing Type

- Impulse Heat Sealing

- Driven Type

- Electric

- Product Type

- Silage Vacuum and Sealing Machine

- Production Capacity

- 600-800 bags/day (varies by bag size)

- Packaging Material

- Plastic Silage Bags

Silage Vacuum and Sealing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Gujarat

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 20 Units Per Week

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Packaging Details

- Standard

- Main Export Market(s)

- Australia, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- iso certified

About Silage Vacuum and Sealing Machine

Key Features:

Efficient Silage Preservation

With advanced vacuum sealing technology, this machine ensures improved preservation and storage of silage and fodder. The powerful vacuum pump removes air before sealing, extending the shelf-life and maintaining nutritional quality. Its impulse heat sealing mechanism produces a secure seal, minimizing spoilage or contamination.

User-Friendly Operation With High Productivity

Equipped with a digital panel or user-friendly push-button controls, the system allows straightforward operation. Capable of handling 600-800 bags per day depending on bag size, this machine supports high-volume use for fodder processing and packaging units. The quick cycle time enhances productivity on busy farms or commercial operations.

Safe and Mobile Design

Built with operator safety in mind, the machine incorporates features such as an emergency stop switch and overload protection. Large caster wheels provide mobility for convenient relocation, making it easy to integrate the machine into existing production environments or move across facilities as needed.

FAQ's of Silage Vacuum and Sealing Machine:

Q: How does the Silage Vacuum and Sealing Machine ensure effective preservation of silage and fodder?

A: The machine uses a high-capacity vacuum pump to remove air from silage bags before sealing, thereby minimizing oxidation and spoilage. This process extends shelf-life and helps retain nutrients in the fodder, making it more suitable for long-term storage and transportation.Q: What types and sizes of bags can this machine handle for sealing?

A: It is designed for use with plastic silage bags and can handle bags with a filling capacity of 20-60 kg per bag. The impulse heat sealing system creates a secure seal with a width of 8-12 mm for various bag sizes.Q: When should the machine's emergency stop feature be used?

A: The emergency stop switch should be activated immediately in case of any operational anomaly, safety risk, or mechanical issue during use. This ensures rapid shutdown and prevents accidents or equipment damage.Q: Where is the ideal setting to operate this vacuum sealing machine?

A: The machine is suitable for use in agricultural facilities, fodder processing units, and packaging centers. Its moderate size and mobility from caster wheels allow easy placement in production lines or storage areas.Q: What benefits does the digital control system offer compared to manual controls?

A: The digital panel or push-button controls enable precise operation, easy adjustment of parameters, and more reliable performance. This improves user experience, reduces setup time, and enhances the consistency of sealed products.Q: How fast can the Silage Vacuum and Sealing Machine complete a sealing cycle?

A: Each sealing cycle takes approximately 15-30 seconds, allowing for rapid processing and high daily output, creating efficiencies in large-scale or commercial operations.Q: What safety features are included for operator protection?

A: The machine is equipped with an emergency stop switch and overload protection to ensure safe operation, reducing the risk of accidents during heavy-duty or continuous use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Silage Machine Category

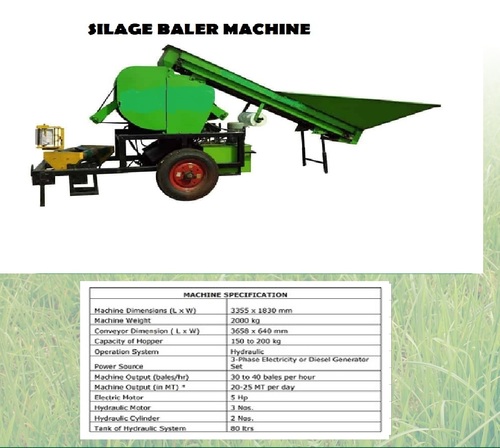

Silage Baler Machine

Price 660000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Filling Capacity : 2530 kg per bale

Automatic Grade : SemiAutomatic

Power : 5 Horsepower (HP)

Dimension (L*W*H) : 2800 x 1700 x 1500 mm

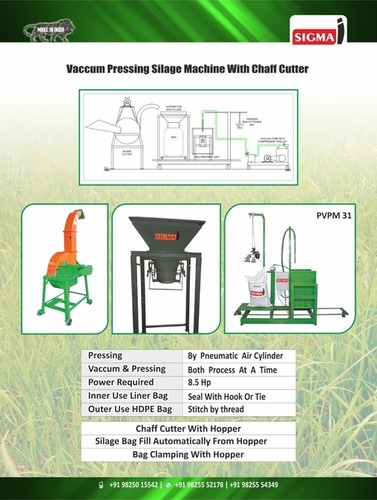

Silage Making Machine

Price 180000 INR / Piece

Minimum Order Quantity : 1 Piece

Filling Capacity : Variable (as per requirement)

Automatic Grade : SemiAutomatic

Power : 8.5 Horsepower (HP)

Dimension (L*W*H) : 3200 x 1650 x 2150 mm

Silage Machine

Price 656000 INR / Unit

Minimum Order Quantity : 1 Unit

Filling Capacity : 50 Kg/day

Automatic Grade : SemiAutomatic

Power : 10 Horsepower (HP)

Dimension (L*W*H) : 10 x 14x 32 Inch (in)

Semi Automatic Silage Bag Packing Machine

Price 468000 INR / Unit

Minimum Order Quantity : 1 Unit

Filling Capacity : 4050 bag Kg/hr

Automatic Grade : SemiAutomatic

|

SIGMA INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry