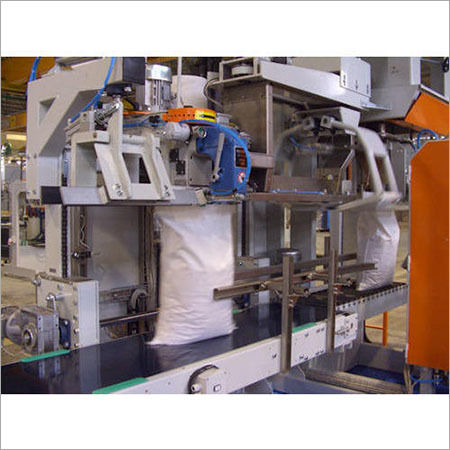

Granules Filling Machine

Price 396000.00 INR/ Unit

Granules Filling Machine Specification

- Machines Type

- Manual

- Product Type

- Granules Filling Machine

- Material

- Mild Steel

- Voltage

- 440 Volt (v)

- Driven Type

- Electric

Granules Filling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Standard

- Main Export Market(s)

- Asia, Australia, Africa

- Main Domestic Market

- All India

About Granules Filling Machine

Buy from us a highly productive Granules Filling Machine that can be used in food, chemical, pharmaceutical, agriculture, and more for fast and efficient filling of powdered, granular, and small solid products in flexible bags. It is designed by our team of professional engineers using advanced technologies making it capable to function at variable speeds and volumetric capacities. The sturdy machine frame of this unit is made up of top-grade engineering materials that provide high rigidity to bear extreme industrial conditions. It requires alternating voltage of 220 to 440 volts with an input frequency of 50 to 60 Hertz. Granules Filling Machine is capable to fill materials in bags with a material carrying capacity of up to 50 Kilograms in a single filling cycle. Buyers can get this energy-efficient machine as per their requirements with an assurance of fast and safe delivery at a reasonable and low price.

Features:

Sturdy and robust design making it capable to bear harsh industrial conditions leading to longer service life.

- Fully automated filling mechanism to fill bags with high precision and accuracy in required amounts.

- Interactive control panel that can be easily controlled by a single operator.

- Efficient material conveying to ensure continuous filling operation.

- Adjustable speed control makes it suitable for different products.

- Highly reliable safety features to ensure safe and controlled operation.

- Compatible with various machines which makes it easy to integrate it within the production line.

FAQs: Granules Filling Machine

What types of granules can be filled using these machines?

Granules Filling Machine designed by our company finds its application in various industrial facilities where it is required to fill substances in plastic pouches and sacks with high accuracy. The offered machine is known for its versatility as it is capable to handle various types of products within industries such as food, agriculture, chemical, pharmaceutical, and more. Some of the common examples of products that can be filled using Granules Filling Machine are sugar, salt, nuts, coffee beans, granular chemicals, detergent granules, food grains, rice, pet food, and more.

What are the advantages of using a granules filling machine?

There are several advantages that make Granules Filling Machine highly demanding within various industries. Some of the key advantages are:

- Increased filling capacity and speed which in turn results in high productivity.

- High filling accuracy and consistency eliminate the risk of material wastage.

- High-class cleanliness makes it ideal for the food and pharmaceutical industries.

- Low power consumption and less maintenance result in low operational costs.

- Fully automated operation that leads to reduced manual labor.

Are granules filling machines customizable for different packaging needs?

The offered industrial-grade Granules Filling Machine are in high demand as these machines can be easily adjusted for the filling of various types of containers as well as to handle various types of granular materials. There are some common ways in which the offered machine can be customized:

- Material Compatibility: Stainless steel coated with a non-corrosive and non-stick coat is used to manufacture components that come into contact with the granules.

- Fill Volume: The advanced sensor-based weighing system of this industrial-grade filling machine can be adjusted which allows you to fill materials from small to large quantities.

- Fill Speed: The speed of the power drives can be easily controlled to meet production demands.

- Container Size and Shape: The adaptable handling mechanism of the machine easily handles different-shaped containers for versatility in packaging options.

- Software and Controls: The software within the machine can be customized to cater to specific production.

What factors should be considered when choosing a granules filling machine?

Choosing the right type of Granules Filling Machine is a crucial step to ensure streamlined production. Given below are some of the key points that need to be considered during the selection of Granules filling machine:

- Determine the daily requirements of your industry, this help you to select machines with the right filling capacity and production rate.

- Compatibility with various types and sizes of granular substances.

- Quality of machine components, structural frame, power drives, and control equipment.

- Automation level and integrity compatibility with machines in the existing production line.

- Compatibility with containers that are going to be filled.

- Technical support from the manufacturer.

How to maintain a granules filling machine?

To keep your Granules Filling Machine in its optimal state, it is recommended to follow below-mentioned maintenance activities:

- Cleaning of the machine frame and its components for the elimination of contaminants that may cause damage to the machine or products to be filled.

- Apply lubricants over moving parts of the machine to reduce wear and tear.

- Check for loose fasteners and if you find any tighten them immediately.

- Perform Scheduled inspection and replace damaged parts.

- Follow the manual and maintenance guide provided by the manufacturer.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Bagging System Category

Big Bag Filling System

Price 490000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Voltage : 440 Volt (v)

Automatic Bag Filling System

Price 3725000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Automatic Bag Filling System

Automatic Grade : Fully Automatic

Driven Type : Electric

Bulk Bagging Systems

Price 468000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Bulk Bagging Systems

Voltage : 400 Volt (v)

Driven Type : Electric

Ad Star Bag Filling Machine

Price 490000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Ad Star Bag Filling Machine

Driven Type : Electric

|

SIGMA INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry