FIBC Bag Filling System

Price 354000 INR/ Unit

FIBC Bag Filling System Specification

- Type

- Filling Machine

- Material

- M.S. and S.S.

- Automatic Grade

- Semi-Automatic

- Power

- 440 Volt (v)

- Dimension (L*W*H)

- 4 x4 x 10 Foot (ft)

FIBC Bag Filling System Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedaabd

- Payment Terms

- Letter of Credit (L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Packaging Details

- Standard Packing

- Main Export Market(s)

- Asia, Australia, Africa

- Main Domestic Market

- All India

- Certifications

- iso certified

About FIBC Bag Filling System

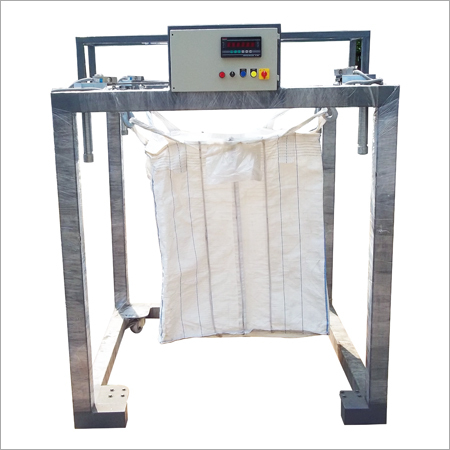

FIBC Bag Filling System

Our FIBC Bag Filling System is engineered for heavy-duty, semi-automatic filling of various bulk materials in a cost-effective and precise manner. Designed for flexible intermediate bulk containers (FIBC), also known as bulk bags, this system is widely used in industries for filling seeds, beans, corn, wheat, cereals, mineral feed, sand, gravel, petrochemicals, fuel, and inorganic fertilizers.

Key Features:

-

Dust Containment: Integrated dust collection ensures a clean and safe working environment.

-

Cost-Effective Operation: Minimizes waste and material spillage while optimizing material usage.

-

Versatile Construction: Contact parts are available in Mild Steel, SS 304, or SS 316 based on client requirements.

-

Flexible Use: Suitable for both semi-automatic and automatic operations.

-

Simple Handling: Compatible with forklifts and cranes for easy bag placement and removal.

Technical Specifications:

-

Model: JBFM01

-

Capacity: 0200 / 250 / 500 / 750 / 1000 / 1500 / 2000 Kgs

-

Resolution: 1/10000

-

Speed: 510 Bags/hr (depending on product nature)

-

Power Supply: 440 V, 3 Phase AC

-

Compressed Air: Dry air, 6 bar pressure

-

Feeding Device: Slide Gate / Sector Gate / Butterfly

-

Dimensions: 4 x 4 x 10 ft

-

Capacity: 1012 BPH

-

Material: M.S. and S.S.

-

Brand: SIGMA

-

Machine Type: Semi-Automatic / Automatic

How It Works:

-

Place the FIBC bag on the support structure.

-

Transfer material using a conveyor or auger system.

-

Weigh the material with load cells to achieve the desired weight.

-

Seal and close the FIBC bag securely.

-

Discharge the filled bag for storage or transportation.

Benefits:

-

High Efficiency: Saves time and labor compared to manual filling.

-

Simple Handling: Compatible with standard lifting equipment.

-

Safety Features:

-

Emergency stop buttons for immediate shutdown

-

Overload protection to prevent equipment damage

-

Secure bag support to prevent collapse during filling

-

Dust containment system to protect operators

-

FAQs of FIBC Bag Filling System:

Q: What is the automatic grade of the FIBC Bag Filling System?

A: The automatic grade of the FIBC Bag Filling System is Semi-Automatic.Q: What type of machine is the FIBC Bag Filling System classified as?

A: The FIBC Bag Filling System is classified as a Filling Machine.Q: What materials are used in the construction of the FIBC Bag Filling System?

A: The FIBC Bag Filling System is made using M.S. (Mild Steel) and S.S. (Stainless Steel).Q: What is the power requirement for the FIBC Bag Filling System?

A: The FIBC Bag Filling System operates at a power supply of 440 Volt (v).Q: What are the dimensions of the FIBC Bag Filling System?

A: The dimensions of the FIBC Bag Filling System are 4 x 4 x 10 feet (L x W x H).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bag Filling Machines Category

Chemical Powder Filling Machine

Price 420000 INR / Set

Minimum Order Quantity : 1 Set

Capacity : 20 to 50 Kg/hr

Type : Filling Machine

Material : Stainless Steel

Automatic Grade : SemiAutomatic

Calcium Carbonate Filling Machine

Price 336000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 20 to 25 Kg/hr

Type : Filling Machine

Material : Powder

Automatic Grade : Automatic

Jumbo Bag Filling System

Price 468000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : 500 1200 Kg/hr

Type : Filling Machine

Material : Stainless Steel

Sand Bag Filling Machine

Price 490000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 400 Kg/hr

Type : Filling Machine

Automatic Grade : SemiAutomatic

|

SIGMA INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry