Tile Adhesive Production Lines

Price 1750000 INR/ Unit

Tile Adhesive Production Lines Specification

- Weight

- 6000-7000 Kilograms (kg)

- Usage

- Industrial

- Condition

- New

Tile Adhesive Production Lines Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 10-15 Days

- Packaging Details

- Standard

About Tile Adhesive Production Lines

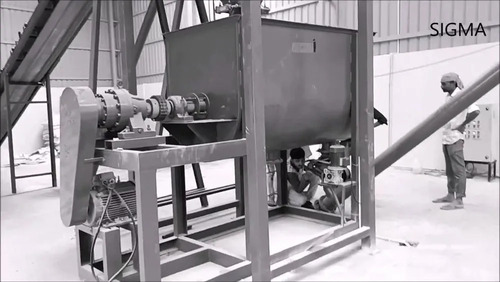

Tile Adhesive Production Lines

Tile Adhesive Production Lines are critical to addressing the demands of the construction and tiling industries. By delivering dependable and long-lasting bonding solutions, they help to expedite the production process, assure product uniformity, and contribute to the success of tile installations.

Tile Adhesive Production Lines enable producers to supply high-quality tile adhesives to the market because of their efficiency, customization choices, and quality control methods. Tile adhesive manufacturing processes can support a wide range of additives and aggregates, allowing the fabrication of varied adhesive formulas for specific tiling applications.

Features: Tile Adhesive Production Lines

-

Advanced quality control systems ensure compliance with industry standards and client specifications by monitoring and confirming adhesive characteristics.

-

They are intended to operate at many sizes, from small-scale batch production to large-scale continuous production.

Mixing and dosing methods that are automated provide constant and accurate formulation.

FAQs: Tile Adhesive Production Lines

How might tile adhesive production lines help to boost productivity?

Tile adhesive manufacturing lines use automated technology and optimized procedures to achieve high production rates, increasing total productivity and satisfying market needs.

How does the automated mixing and dosing procedure ensure that tile adhesives are uniform and of good quality?

The automated mixing and dosing techniques used on the production lines provide exact formulation.

How can tile adhesive production lines aid in labor cost reduction?

Automation of the manufacturing process minimizes the need for human labor, resulting in lower labor costs.

FAQs of Tile Adhesive Production Lines:

Q: What is the drive type of the Tile Adhesive Production Lines?

A: The Tile Adhesive Production Lines operate with an electric drive type.Q: What is the automatic grade of the Tile Adhesive Production Lines?

A: The Tile Adhesive Production Lines are semi-automatic.Q: What is the warranty period for the Tile Adhesive Production Lines after installation?

A: The product comes with a 12-month warranty after installation.Q: What is the weight range of the Tile Adhesive Production Lines?

A: The Tile Adhesive Production Lines weigh between 6000 and 7000 kilograms (6-7 tonnes).Q: What are the dimensions of the Tile Adhesive Production Lines?

A: The dimensions of the Tile Adhesive Production Lines are 20 x 60 feet (L x W).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sigma Tile Adhesive Plant Category

Tile Adhesive Plant Machine

Price 1400000.00 INR / Plant

Minimum Order Quantity : 1 Plant

Drive Type : Electric

Product Type : Tile Adhesive Plant Machine

Condition : New

Automatic Grade : SemiAutomatic

Floor Tile Adhesive manufacturing plant

Price 1300000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Product Type : Floor Tile Adhesive manufacturing plant

Condition : New

Automatic Grade : SemiAutomatic

|

SIGMA INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry