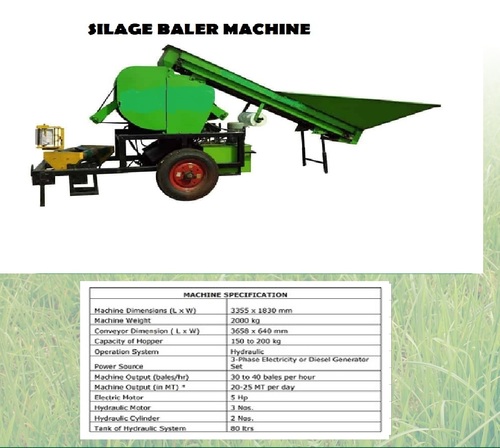

Silage Baler Machine

Price 660000.00 INR/ Piece

Silage Baler Machine Specification

- Dimension (L*W*H)

- 2800 x 1700 x 1500 mm

- Filling Capacity

- 25-30 kg per bale

- Product Type

- Silage Baler Machine

- Driven Type

- Hydraulic

- Packaging Material

- Plastic Film

- Power

- 5 Horsepower (HP)

- Material

- Mild Steel

- Input Power

- Electric

- Voltage

- 380 V

- Sealing Type

- Heat Sealing

- Control System

- PLC Controlled

- Machines Type

- Baling Machine

- Electric Current Type

- Three Phase

- Production Capacity

- 300-400 bales per day

- Weight

- 2000 Kilograms (kg)

- Automatic Grade

- Semi-Automatic

- Noise Level

- Less than 70 dB

- Moisture Content Range

- 40-65%

- After Sales Service

- Available

- Application

- For baling silage, forage, and animal feed

- Bale Size

- 700 x 400 x 400 mm

- Color

- Green

- Cycle Time

- 35-45 seconds per bale

- Operation Mode

- Manual/Automatic

- Safety Features

- Overload protection, emergency stop

Silage Baler Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 20 Pieces Per Week

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Packaging Details

- Standard

- Main Export Market(s)

- Australia, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- iso certified

About Silage Baler Machine

They are essential in contemporary agriculture and animal sectors. These devices are meant to collect, condense, and store fodder crops, which are generally used as animal feed. Silage baler machinery is in high demand because to the expanding global demand for dairy products. The demand for efficient and cost-effective fodder harvesting and storage solutions develops as livestock businesses develop to satisfy rising food demand.

Features,

- It is intended to efficiently manage vast amounts of feed.

- It is outfitted with cutting systems that collect forage crops and prepare them for baling.

- It allows for the creation of bales of varying sizes to satisfy individual animal feeding requirements.

FAQs : Silage Baler Machine

Are such devices long-lasting?These machines are made of heavy-duty materials to endure the rigors of the agricultural environment.

Is the maximum output adjustable to meet individual needs?

While the maximum production of the machine is indicated as 30 to 40 bales per hour, it may be modified to some amount.

Is the equipment capable of producing a steady output throughout its operation?

The machine's capacity to provide a constant output is determined by a variety of factors, including fodder type, field conditions, and operator competency.

Precision Baling for Enhanced Feed Storage

Engineered for optimum efficiency, the Silage Baler Machine guarantees precise bale sizes and uniform sealing. Its hydraulic mechanism and PLC control enable consistent results, reducing manual intervention and improving productivity. Suitable for a range of moisture contents, this baler is instrumental in preserving nutritional quality and simplifying transportation.

User-Friendly Operation and Reliable Safety

Choose between manual or automatic modes to suit your workflow. Safety is ensured through overload protection and an emergency stop feature, safeguarding operators during intensive use. The noise level remains below 70 dB, contributing to a comfortable working environment in agricultural facilities.

Comprehensive After-Sales Support

Rest assured with dedicated after-sales service from a reputable exporter and manufacturer in India. Technical guidance, maintenance, and spare parts supply are readily available, allowing uninterrupted operation and maximizing the machines lifespan.

FAQs of Silage Baler Machine:

Q: How does the Silage Baler Machine improve the storage and transport of animal feed?

A: The machine compresses silage, forage, or animal feed into compact bales, each wrapped and heat-sealed with plastic film. This preserves moisture (4065%) and nutritional value, making handling, storage, and transport more efficient and hygienic.Q: What is the baling process for this machine, and what control systems are available?

A: Material is loaded for filling, compressed hydraulically, and then sealed using heat. The PLC-controlled system automates key operations, ensuring cycle times of 3545 seconds per bale, with options for both manual and automatic modes depending on user preference.Q: When should I use the manual vs. automatic mode?

A: Manual mode is preferred during initial setup, troubleshooting, or when processing requires direct supervision. Automatic mode is ideal for bulk operations, allowing continuous baling with minimal intervention for optimal production rates.Q: Where is this baling machine best utilized?

A: The baler is well-suited for agricultural sectors requiring efficient silage, forage, and feed packagingsuch as dairy farms, livestock operations, and feed suppliers throughout India and export destinations.Q: What safety measures are included with the baler machine?

A: To protect users, the machine incorporates overload protection that prevents excessive stress on components, and an emergency stop button to immediately halt operations if needed.Q: What are the benefits of the heat-sealed packaging system?

A: Heat sealing ensures each bale is securely wrapped, maintaining feed quality by preventing moisture loss and contamination. It also improves shelf life and simplifies logistics.Q: How does after-sales service support customers?

A: After-sales service includes technical assistance, regular maintenance, and the supply of spare parts, ensuring the machine remains fully operational and reducing downtime for users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Silage Machine Category

Silage Vacuum and Sealing Machine

Price 1250000 INR / Unit

Minimum Order Quantity : 1 Unit

Filling Capacity : 2060 kg per bag

Automatic Grade : SemiAutomatic

Product Type : Silage Vacuum and Sealing Machine

Dimension (L*W*H) : 1220 mm x 680 mm x 1020 mm

Silage Making Machine

Price 180000 INR / Piece

Minimum Order Quantity : 1 Piece

Filling Capacity : Variable (as per requirement)

Automatic Grade : SemiAutomatic

Product Type : Silage Making Machine

Dimension (L*W*H) : 3200 x 1650 x 2150 mm

Silage Machine

Price 656000 INR / Unit

Minimum Order Quantity : 1 Unit

Filling Capacity : 50 Kg/day

Automatic Grade : SemiAutomatic

Dimension (L*W*H) : 10 x 14x 32 Inch (in)

Semi Automatic Silage Bag Packing Machine

Price 468000 INR / Unit

Minimum Order Quantity : 1 Unit

Filling Capacity : 4050 bag Kg/hr

Automatic Grade : SemiAutomatic

Product Type : Semi Automatic Silage Bag Packing Machine

|

SIGMA INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry